Current list of equipment & capabilities, updated regularly.

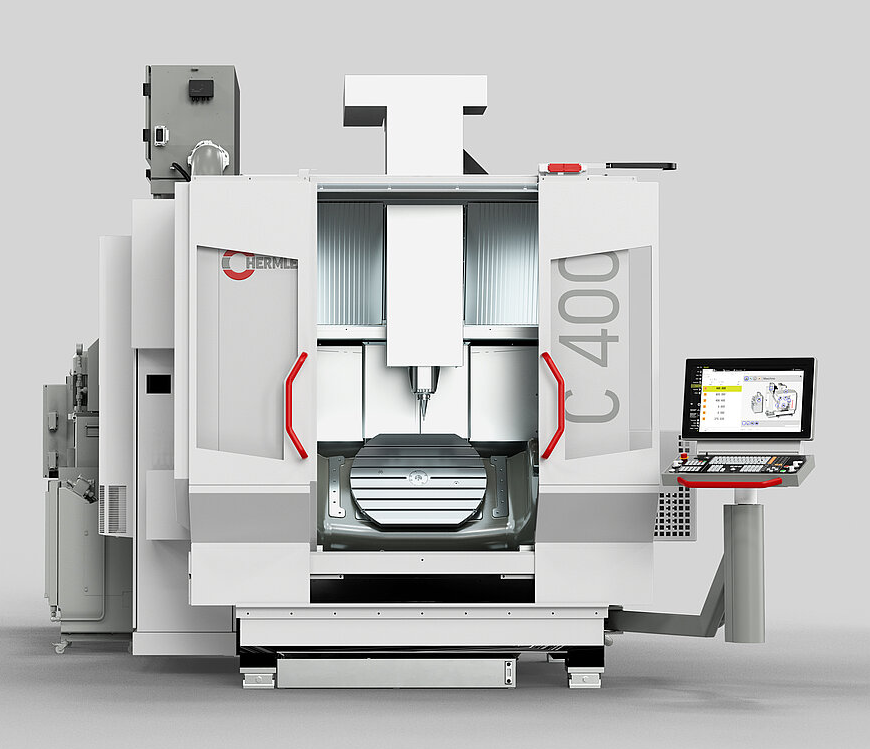

5 axis CNC Machining

Hermle C400 850x700x500mm travels - Made in Germany

Equipped with through spindle coolant and probes

Full thermal comp, glass scales on all axis

38 tool ATC, 18k spindle, 600kg max table load

3 axis CNC Machining

Brother S700X2 700x400x300mm travels - Made in Japan

Equipped with through spindle coolant and probes

21 tool ATC, 16k spindle

Fork lift & loading dock

Ship and receive raw materials and completed goods

In house black oxide

Conversion coating process for ferrous metals - moderate corrosion resistance and negligible buildup

Complete control over process and lead time, no reliance on outside suppliers

In house heat treating

12”x12”x10” interior furnace dimensions, 2000 degrees

Hardness testing equipment to validate results

Complete control over process and lead time, no reliance on outside suppliers

Capable of hardening, tempering, annealing, normalizing, stress relief, and more

Ideally suited for air hardening tool steel (A2, S7, D2, H13) but also capable of oil or water quench.

Equipped to hard machine components to finish dimension after heat treat

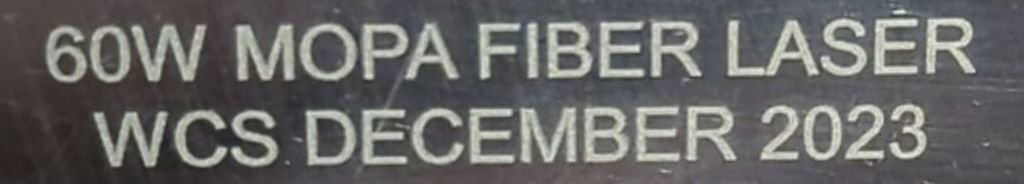

60W Galvo Fiber Laser (JPT MOPA laser source)

High speed marking of almost any material

Etch part number, lot number, serial number, date of manufacture, etc.

175mmx175mm marking area (~7” square)

Color marking of stainless and titanium

3D Printing (Bambu X1C w/ AMS)

PLA, ABS, PA (nylon), PETG

Glass or carbon fiber reinforced filament options

Automatic color & material swapping, capable of multi color and multi material prints

256x256x256 build volume (~10” cube)

Band saw

Capacity: 7” round stock; 7” x 12” rectangular stock

Inspection

.061-.5005 gage pins, .0005” increment, minus tolerance, +0/-.0002

Gage block sets

Assorted inside and outside micrometers with standards

Pitch micrometers

Bore gages

Thread go no-go gages

Granite surface plate

Assorted indicators, .0005” and .0001” division

Microscope